Ukudayiswa kabusha kuyisinyathelo esibalulekile kunqubo ye-SMT.Iphrofayili yezinga lokushisa ehambisana nokugeleza kabusha iyipharamitha ebalulekile yokulawula ukuze kuqinisekiswe ukuxhumana okufanele kwezingxenye.Amapharamitha ezingxenye ezithile azophinde athinte ngqo iphrofayili yezinga lokushisa elikhethelwe leso sinyathelo senqubo.

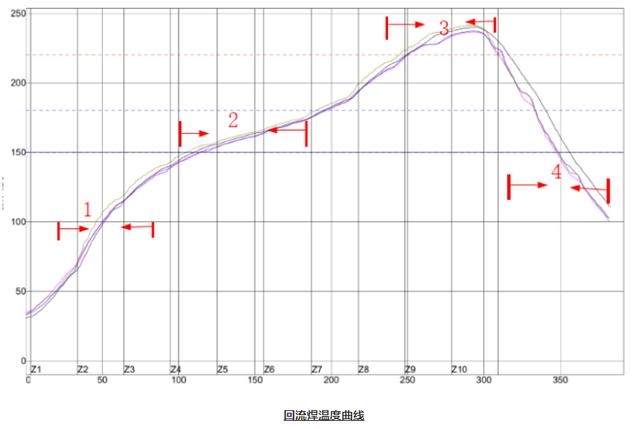

Ku-conveyor enamathrekhi amabili, amabhodi anezingxenye ezisanda kubekwa adlula ezindaweni ezishisayo nezibandayo zehhavini eligeleza kabusha.Lezi zinyathelo zenzelwe ukulawula ngokunembile ukuncibilika nokupholisa kwe-solder ukugcwalisa amalunga e-solder.Ukushintsha kwezinga lokushisa okuyinhloko okuhlotshaniswa nephrofayili yokugeleza kabusha kungahlukaniswa ngezigaba/izifunda ezine (ezibalwe ngezansi futhi ziboniswe kamuva):

1. Zifudumeze

2. Ukushisa njalo

3. Izinga lokushisa eliphezulu

4. Ukupholisa

1. Indawo yokushisa

Inhloso yendawo yokushisisa ukushisisa iwukushintshanisa ama-solvent point ancibilika ku-solder paste.Izingxenye eziyinhloko ze-flux ku-solder paste zifaka ama-resin, ama-activator, ama-viscosity modifiers nama-solvents.Indima ye-solvent ngokuyinhloko njengesithwali se-resin, nomsebenzi owengeziwe wokuqinisekisa ukugcinwa okwanele kwe-solder paste.Indawo yokushisa yangaphambili idinga ukushisisa isincibilikisi, kodwa izinga lokushisa elikhuphukayo kufanele lilawulwe.Izilinganiso zokushisisa ngokweqile zingacindezela ingxenye, engalimaza ingxenye noma yehlise ukusebenza kwayo/impilo yayo yonke.Omunye umphumela ohlangothini wezinga lokushisa eliphezulu kakhulu ukuthi i-solder paste ingawa futhi ibangele izifunda ezimfushane.Lokhu kuyiqiniso ikakhulukazi kuma-solder pastes anokuqukethwe okuphezulu kwe-flux.

2. Indawo yokushisa ehlala njalo

Ukulungiselelwa kwendawo yokushisa engaguquki kulawulwa ikakhulukazi ngaphakathi kwemingcele yomhlinzeki we-solder unama kanye nomthamo wokushisa we-PCB.Lesi sigaba sinemisebenzi emibili.Okokuqala ukufeza izinga lokushisa elifanayo lebhodi le-PCB lonke.Lokhu kusiza ukunciphisa imiphumela yokucindezeleka okushisayo endaweni yokugeleza kabusha futhi kukhawule okunye ukukhubazeka kwe-solder njengokuphakanyiswa kwengxenye yevolumu enkulu.Omunye umphumela obalulekile walesi sigaba ukuthi i-flux in the solder paste iqala ukusabela ngobudlova, ikhulise ukumanzisa (kanye namandla angaphezulu) kwendawo yokushisela.Lokhu kuqinisekisa ukuthi i-solder encibilikisiwe imanzisa indawo ehlanganisiwe kahle.Ngenxa yokubaluleka kwale ngxenye yenqubo, isikhathi sokucwilisa kanye nezinga lokushisa kufanele kulawulwe kahle ukuze kuqinisekiswe ukuthi i-flux ihlanza ngokuphelele izindawo ze-soldering nokuthi i-flux ayidliwe ngokuphelele ngaphambi kokuba ifinyelele inqubo ye-reflow soldering.Kuyadingeka ukugcina i-flux ngesikhathi sesigaba sokugeleza kabusha njengoba kusiza inqubo yokumanzisa i-solder futhi ivimbele ukuphinda kufakwe i-oxidation yendawo edayisiwe.

3. Indawo yokushisa ephezulu:

Indawo yokushisa ephezulu yilapho ukusabela okuphelele kokuncibilika nokumanzisa kwenzeka lapho ungqimba oluphakathi kwe-intermetallic luqala ukwakha.Ngemva kokufinyelela izinga lokushisa eliphezulu (ngaphezu kuka-217 ° C), izinga lokushisa liqala ukwehla futhi liwela ngaphansi komugqa wokubuyisela, emva kwalokho i-solder iqinisa.Le ngxenye yenqubo nayo idinga ukulawulwa ngokucophelela ukuze irempu yokushisa eya phezulu naphansi ingafaki ingxenye ekushaqekeni okushisayo.Izinga lokushisa eliphezulu endaweni yokugeleza kabusha linqunywa ukumelana nezinga lokushisa kwezingxenye ezizwela ukushisa ku-PCB.Isikhathi endaweni yokushisa ephezulu kufanele sibe mfushane ngangokunokwenzeka ukuze kuqinisekiswe ukuthi izingxenye zishisela kahle, kodwa hhayi isikhathi eside kangangokuthi ungqimba lwe-intermetallic luba lukhulu.Isikhathi esifanelekile kule zoni ngokuvamile imizuzwana engama-30-60.

4. Indawo yokupholisa:

Njengengxenye yenqubo yokuphinda kufakwe i-reflow soldering, ukubaluleka kwezindawo zokupholisa ngokuvamile akunakwa.Inqubo yokupholisa enhle nayo idlala indima ebalulekile ekugcineni kwe-weld.Ukuhlanganiswa kwe-solder okuhle kufanele kube okukhanyayo futhi okuyisicaba.Uma umphumela wokupholisa ungemuhle, izinkinga eziningi zizokwenzeka, njengokuphakama kwengxenye, amajoyinti amnyama e-solder, izindawo ezihlangene ze-solder ezingalingani kanye nokuqina kongqimba oluhlanganisiwe lwe-intermetallic.Ngakho-ke, i-reflow soldering kufanele inikeze iphrofayili enhle yokupholisa, hhayi ngokushesha kakhulu noma engasheshi kakhulu.Ihamba kancane kakhulu futhi uthola ezinye zezinkinga zokupholisa ezimbi ezishiwo ngenhla.Ukupholisa ngokushesha kakhulu kungabangela ukushaqeka okushisayo ezingxenyeni.

Sekukonke, ukubaluleka kwesinyathelo sokugeleza kabusha kwe-SMT akunakubukelwa phansi.Inqubo kumele ilawulwe kahle ukuze kube nemiphumela emihle.

Isikhathi sokuthumela: May-30-2023