I-Reflow soldering (i-reflow soldering/oven) iyindlela esetshenziswa kakhulu yokuhlanganisa ingxenye engaphezulu embonini ye-SMT, futhi enye indlela yokuhlanganisa i-wave soldering (Wave soldering).I-Reflow soldering ifanele izingxenye ze-SMD, kuyilapho i-wave soldering ifanele Okwezingxenye ze-electronic pin.Ngokuzayo ngizokhuluma ngqo ngomehluko phakathi kwalokhu okubili.

I-Reflow Soldering

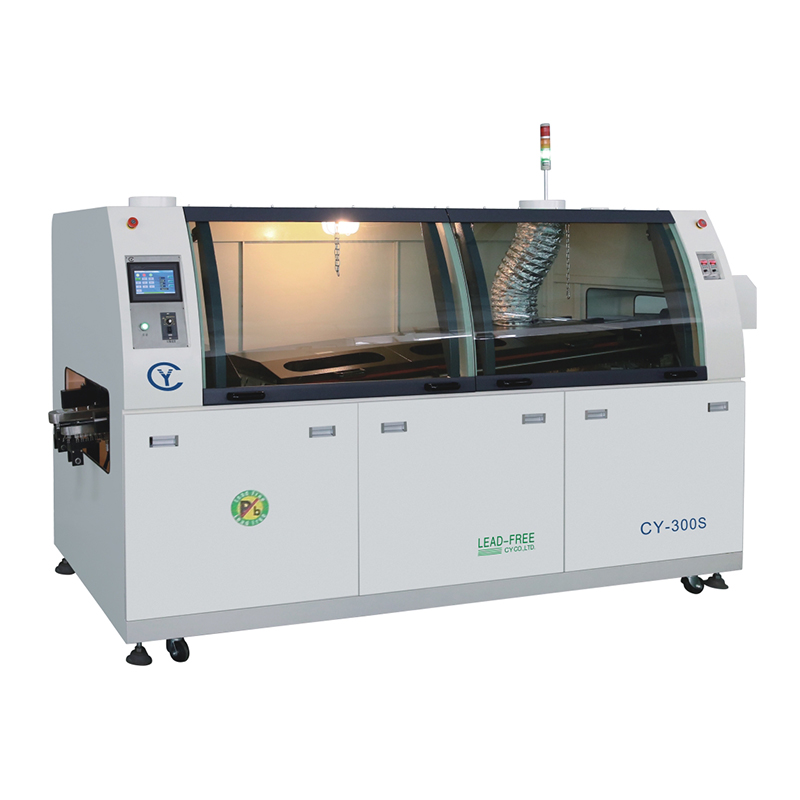

I-Wave Soldering

I-Reflow soldering nayo iyinqubo yokuphinda i-reflow soldering.Umgomo wayo ukuphrinta noma ukujova inani elifanele lokunamathisela kwe-solder (I-Solder paste) kuphedi ye-PCB bese ufaka izingxenye ezihambisanayo zokucubungula chip ye-SMT, bese usebenzisa ukushisisa kwe-convection yomoya oshisayo we-ovini yokugeleza kabusha ukushisa ithini Ukunamathisela kuyancibilika. futhi kwakhiwa, futhi ekugcineni i-solder ethembekile ihlangene yakhiwa ngokupholisa, futhi ingxenye ixhunywe ku-PCB pad, edlala indima yokuxhumeka kwemishini kanye nokuxhumeka kukagesi.Inqubo ye-reflow soldering iyinkimbinkimbi futhi ihilela ulwazi olubanzi.Iyingxenye yomkhakha omusha wezobuchwepheshe.Ngokuvamile, i-reflow soldering ihlukaniswe ngezigaba ezine: ukushisa kuqala, izinga lokushisa elingashintshi, ukugeleza kabusha, nokupholisa.

1. Indawo yokushisa

Indawo yokushisa: Yisigaba sokuqala sokushisa somkhiqizo.Inhloso yawo ukushisa umkhiqizo ngokushesha ekamelweni lokushisa futhi usebenzise i-solder paste flux.Kuphinde futhi kugwenywe ukushisa kwengxenye okubangelwa ukushisa kwezinga eliphezulu lokushisa ngokushesha phakathi nesigaba esilandelayo sethayela lokucwiliswa.Indlela yokushisisa edingekayo ngomonakalo.Ngakho-ke, izinga lokushisa libaluleke kakhulu kumkhiqizo, futhi kufanele lilawulwe ngaphakathi kwebanga elifanele.Uma kushesha kakhulu, ukushaqeka okushisayo kuzokwenzeka, futhi ibhodi le-PCB kanye nezingxenye zizoba ngaphansi kokucindezeleka okushisayo, okubangela ukulimala.Ngesikhathi esifanayo, i-solvent ku-solder paste izoshabalala ngokushesha ngenxa yokushisa okusheshayo.Uma ihamba kancane, i-solder paste solvent ngeke ikwazi ukuguquguquka ngokugcwele, okuzothinta ikhwalithi ye-solder.

2. Indawo yokushisa ehlala njalo

Indawo yokushisa eqhubekayo: inhloso yayo ukuzinzisa izinga lokushisa lengxenye ngayinye ku-PCB futhi kufinyelelwe esivumelwaneni ngangokunokwenzeka ukuze kuncishiswe umehluko wezinga lokushisa phakathi kwezingxenye.Kulesi sigaba, isikhathi sokushisa sengxenye ngayinye side kakhulu.Isizathu siwukuthi izingxenye ezincane zizofinyelela ukulingana kuqala ngenxa yokumuncwa okuncane kokushisa, futhi izingxenye ezinkulu zizodinga isikhathi esanele ukuze zibambe izingxenye ezincane ngenxa yokumuncwa okukhulu kokushisa.Futhi qinisekisa ukuthi i-flux ku-solder paste iguquguquka ngokugcwele.Kulesi sigaba, ngaphansi kwesenzo se-flux, ama-oxides kuma-pads, amabhola e-solder kanye nezikhonkwane zezingxenye zizosuswa.Ngasikhathi sinye, i-flux izophinde isuse uwoyela ebusweni bezingxenye namapads, yandise indawo yokunamathisela, futhi ivimbele izingxenye ukuthi zingaphinde zifakwe i-oxidized.Ngemva kokuba lesi sigaba sesiphelile, ingxenye ngayinye kufanele igcinwe ezingeni lokushisa elifanayo noma elifanayo, ngaphandle kwalokho kungase kube khona ukusoda okungekuhle ngenxa yomehluko omkhulu wokushisa.

Izinga lokushisa nesikhathi sokushisa okungaguquki kuncike enkimbinkingeni yomklamo we-PCB, umehluko ezinhlotsheni zezingxenye kanye nenani lezingxenye, ngokuvamile phakathi kuka-120-170 ° C, uma i-PCB iyinkimbinkimbi ikakhulukazi, izinga lokushisa lendawo yokushisa engashintshi. kufanele kunqunywe ngezinga lokushisa elithambile le-rosin njengereferensi, inhloso Ukunciphisa isikhathi sokudayiswa endaweni yokugeleza kabusha kwe-back-end, indawo yokushisa engashintshi yenkampani yethu ngokuvamile ikhethwa kuma-degree angu-160.

3. Indawo yokugeleza kabusha

Inhloso ye-reflow zone ukwenza i-solder paste ifinyelele esimweni esincibilikisiwe futhi imanzise amaphedi ebusweni bezingxenye ezizothengiswa.

Lapho ibhodi le-PCB lingena endaweni yokugeleza kabusha, izinga lokushisa lizokhuphuka ngokushesha ukwenza i-solder paste ifinyelele esimweni sokuncibilika.Indawo encibilikayo yokunamathisela kwe-solder eholayo Sn:63/Pb:37 ingu-183°C, kanye ne-lead-free solder paste Sn:96.5/Ag:3/Cu: Indawo yokuncibilika engu-0.5 ngu-217°C.Kule ndawo, ukushisa okuhlinzekwa yi-heater kukhulu kakhulu, futhi izinga lokushisa lomlilo lizobekwa phezulu kakhulu, ukuze izinga lokushisa le-solder paste likhuphukele ekushiseni okuphezulu ngokushesha.

Izinga lokushisa eliphakeme lejika le-reflow soldering ngokuvamile linqunywa indawo yokuncibilika ye-solder paste, ibhodi le-PCB, kanye nezinga lokushisa elimelana nokushisa lengxenye ngokwayo.Izinga lokushisa eliphakeme lomkhiqizo endaweni yokugeleza kabusha liyahlukahluka kuye ngohlobo lwe-solder paste esetshenzisiwe.Ngokuvamile, akukho Izinga lokushisa eliphakeme kakhulu le-lead solder paste ngokuvamile lingama-230-250°C, kanti lelo lokunamathisela ngomthofu we-solder ngokuvamile lingama-210-230°C.Uma izinga lokushisa eliphakeme liphansi kakhulu, lizobangela kalula ukushisela okubandayo kanye nokumanzisa okunganele kwamalunga e-solder;uma iphezulu kakhulu, i-epoxy resin type substrates izoba Futhi ingxenye yepulasitiki ijwayele ukupheka, i-PCB igwebu futhi i-delamination, futhi izoholela ekwakhekeni kwezinhlanganisela zensimbi ze-eutectic ngokweqile, okwenza amalunga e-solder abe brittle, enze buthaka amandla okushisela, kanye nokuthinta izici zemishini zomkhiqizo.

Kufanele kugcizelelwe ukuthi ukugeleza kokunamathisela kwe-solder endaweni yokugeleza kuyasiza ukukhuthaza ukumanzisa kwe-solder paste kanye nokuphela kwe-solder yengxenye ngalesi sikhathi, futhi kunciphise ukungezwani okungaphezulu kokunamathisela kwe-solder.Nokho, ngenxa yensalela yomoya-mpilo kanye nama-oxide angaphezulu kwensimbi esithandweni sokugeleza kabusha, Ukugqugquzelwa kokugeleza kusebenza njengesivikelo.

Ngokuvamile ijika lezinga lokushisa elihle lesithando somlilo kufanele lihlangabezane nezinga lokushisa eliphakeme lephoyinti ngalinye ku-PCB ukuze lilingane ngangokunokwenzeka, futhi umehluko akufanele weqe ama-degree angu-10.Kungale ndlela kuphela lapho singaqinisekisa ukuthi zonke izenzo zokuhlanganisa ziqedwe ngempumelelo lapho umkhiqizo ungena endaweni yokupholisa.

4. Indawo yokupholisa

Inhloso yendawo yokupholisa ukupholisa ngokushesha izinhlayiya ezincibilikisiwe zokunamathisela i-solder, futhi wenze ngokushesha amajoyinti akhanyayo ane-arc ehamba kancane kanye nokuqukethwe kwe-tin egcwele.Ngakho-ke, amafektri amaningi azolawula indawo yokupholisa, ngoba ihambisana nokwakhiwa kwamalunga e-solder.Ngokuvamile, izinga lokupholisa elishesha kakhulu lizokwenza ukunamathisela kwe-solder encibilikisiwe kwephuze kakhulu ukuthi kuphole futhi kugcine isisila, okuholela ekwenziweni komsila, ukulola ngisho nama-burrs kumajoyinti e-solder akhiwe.Izinga lokupholisa eliphansi kakhulu lizokwenza indawo eyisisekelo ye-PCB pad surface Izinto ezisetshenziswayo zixutshwe ku-solder paste, okwenza amajoyinti e-solder abe mahhadladla, ahlanganise angenalutho kanye namajoyinti amnyama e-solder.Ngaphezu kwalokho, wonke omagazini bensimbi emaphethelweni e-soldering ezingxenyeni zizoncibilika ezingxenyeni ze-soldering, okubangela ukuthi iziphetho ze-soldering zezingxenye zimelane nokumanzisa noma ukugoqa okungalungile.Ithinta ikhwalithi ye-solder, ngakho-ke izinga lokupholisa elihle libaluleke kakhulu ekubunjweni kokuhlangana kwe-solder.Ngokuvamile, abahlinzeki be-solder paste bazoncoma izinga lokupholisa elihlangene le-solder elingu-≥3°C/S.

I-Chengyuan Industry yinkampani egxile ekuhlinzekeni ngemishini yokukhiqiza ye-SMT ne-PCBA.Ikunikeza ikhambi elifaneleka kakhulu kuwe.Ineminyaka eminingi yokukhiqiza kanye nesipiliyoni socwaningo.Ochwepheshe abaqeqeshiwe banikeza isiqondiso sokufaka kanye nesevisi yendlu ngendlu ngemva kokuthengisa, ukuze ungabi nazinkathazo.

Isikhathi sokuthumela: Mar-06-2023