6. Ibhodi linyakaziswa ngokuzenzakalelayo, futhi ububanzi be-tin wave wave peak bungalungiswa ukuze kuncishiswe inani le-tin oxidation.

7. 1800mm uhlobo olunwetshiwe lwesigaba sesithathu (esine) sokushisa kwangaphambili, i-infrared (umoya oshisayo) ukulawula izinga lokushisa elizimele le-PID, Ngisho nokushisa, kuphephile futhi kuzinzile

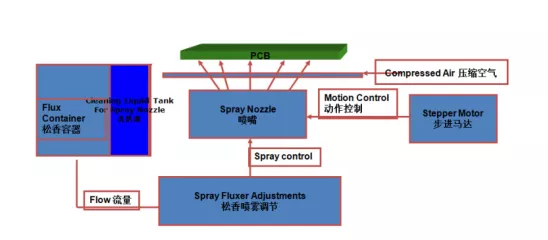

◆ Ngombobo we-Lumina (Japan), ububanzi besifutho bungama-20-65mm, ubude benobhobho bungu-50-80mm, kanti izinga lokugeleza eliphezulu lingu-60ml/min.

◆ Isebenzisa isihlungi se-AirTAC (i-Taiwan), igeji yesikhombi ikhombisa umfutho womoya, wonke amapayipi esistimu yokufafaza anamapayipi okuvikela ukugqwala ane-asidi kanye ne-alkali.

◆ Isistimu yokufafaza isebenzisa indlela yokuskena yokufafaza, ukushintshwa komkhawulo kanye nokubona kokungena kuhlangene ukuze kulawuleke, futhi i-PCB itholwa ngokuzenzakalelayo ngokufafaza okungenayo ngokwejubane nobubanzi be-PCB, ukuze uhla lokumanzisa lokugeleza lufinyelele umphumela omuhle kakhulu.Ikhanda lokufafaza le-inlet kanye ne-steping motor kusebenza kahle, kuzinzile futhi kuthembekile.

◆ I-stainless steel bent forming tray isetshenziswa ngaphansi kwekhanda lesifutho ukuze kulayishwe amanzi angcolile kanye nokugeleza, angakhishwa futhi ahlanzwe ngokuthanda kwakhe.

◆ Isistimu yokukhipha umoya iwuhlelo oluphakeme oluzenzakalelayo lokubuyisela olunezingqimba ezintathu zokuhlunga kwezintambo zensimbi engagqwali ukuze kuncishiswe ukuvaleka kokugeleza okusele epayipini elikhipha umoya ngokusebenzisa izici zoketshezi ukuze kuhlungwe ukugeleza okukhulu.

◆ Ummese womoya womoya, ophephula ukugeleza ngokweqile ngesikhathi sokufafaza ethangini lokubuyisela ukuvimbela ukugeleza kungangeni endaweni yokushisa kuqala futhi kuqinisekiswe ukuphepha kokukhiqiza.

◆ Zonke insimbi engagqwali + i-aluminium alloy support, ukuhlanza okulula nokugcinwa, ukumelana nokugqwala okuqinile, okuhlala isikhathi eside.

Welding System

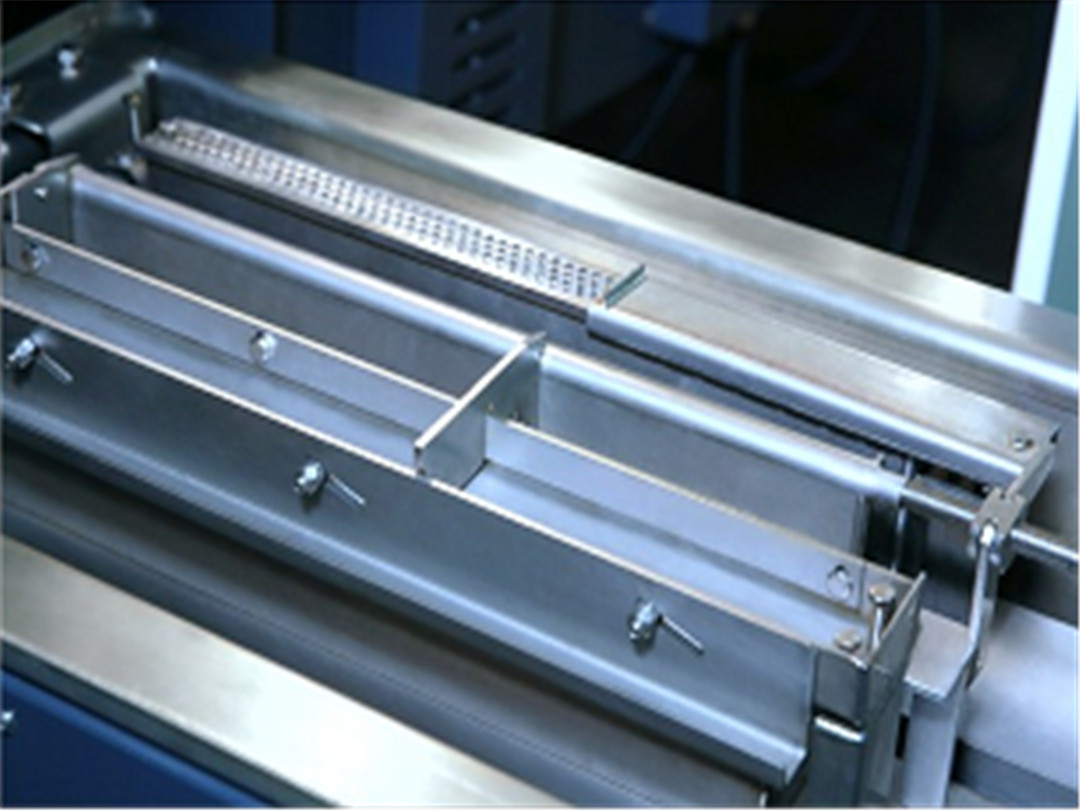

1. 4mm SUS316L Ilayini yomlilo yensimbi engenasici engenisiwe, idizayini entsha yelayini yesithando somlilo, ukubukeka okuhle, ukuhlanzeka kalula, ipuleti lokushisisa lensimbi, ulayini womlilo awukhubazekile

2. I-wave wave crest, ijethi eqondisiwe, i-soldering engcono kakhulu yezingxenye ze-SMD, i-wave crest ibushelelezi njengesibuko

3. Ububanzi be-wave peak buyalungiseka ukuze kuncishiswe inani le-tin oxidation, futhi isihlungi singakhishwa ngaphandle kokuhlakaza umlomo wombhobho.

4. Khulisa ikhava ye-anti-oxidation endaweni ye-impeller shaft ukuze unciphise inani le-tin oxidation elibangelwa ukujikeleza kwe-impeller shaft

5. I-impeller shaft ne-wave motor ingahlakazwa ngokuhlukana ngaphandle kokuhlakaza isiteshi sikathayela (ezinye izinhlobo ze-wave soldering azikwazi ukwenza lo mklamo)

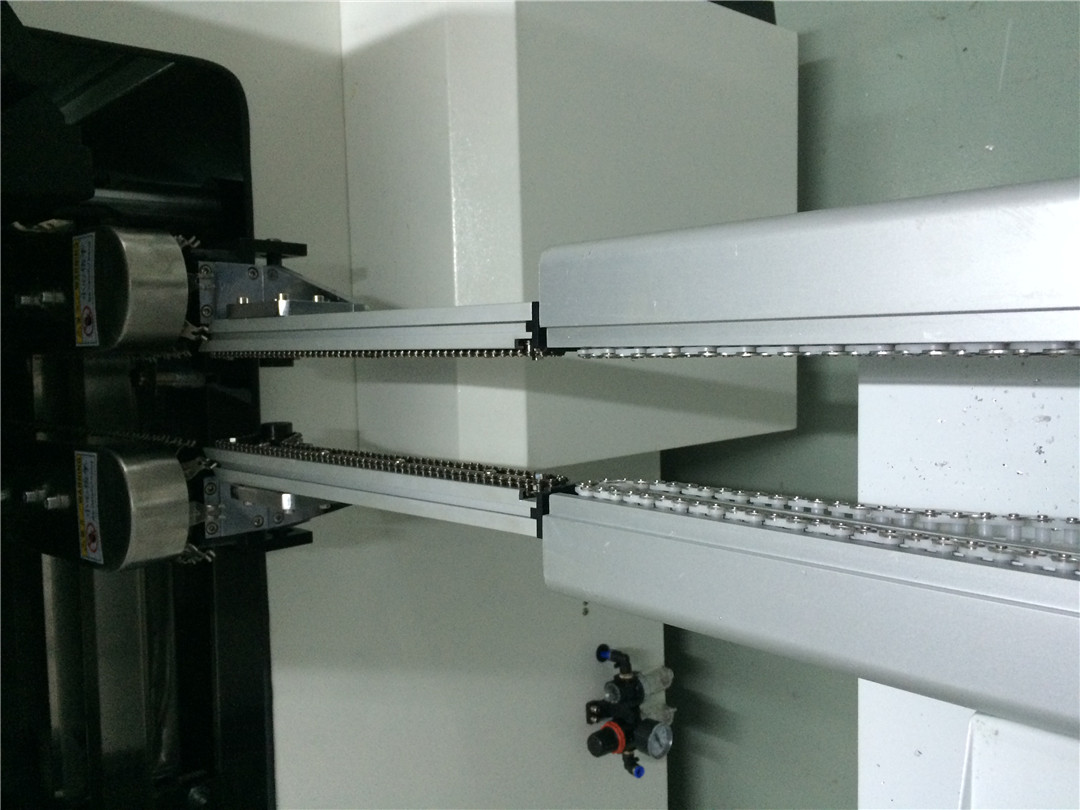

Uhlelo lwezokuthutha

I-aluminium ehlanzekile ehlanzekile yokuphakelayo kanye nedivayisi yokuxhuma, ukondla okubushelelezi futhi okuzinzile, ukulungiswa okuhle kakhulu

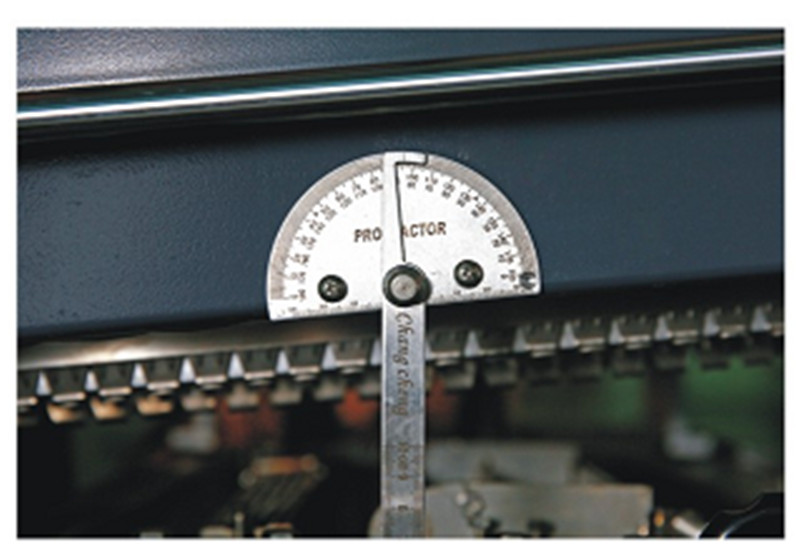

Umzila wesitimela unedivayisi yawo ye-engeli etshekile, engaqapha ngokunembile i-engeli etshekile futhi ilawule ikhwalithi yebhodi.

Izingwegwe ze-Titanium alloy claw ziqinisekisa ukuthi ithini alisoze langcoliswa, futhi ama-rails angumhlahlandlela anezigaba ezintathu aqinisekisa ukuthi ama-guide rails awasoze avutha, okuvimbela ngempumelelo ama-rails ukuba angawi futhi aminyene.

◆Ubuhlalu bethusi obungu-4mm benza inqubo yokuthutha ibe bushelelezi futhi izinze.(Iningi lezinye izinhlobo zisebenzisa insimbi engagqwali layering, engakwazi ukuqinisekisa ukuhamba okubushelelezi isikhathi eside.)

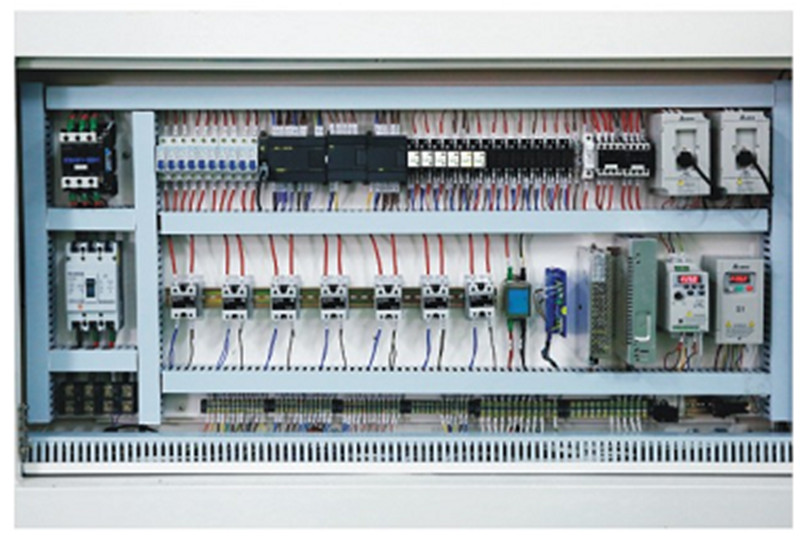

Uhlelo lokusebenza olwenziwe lula lulungele abasebenzi ukuthi balusebenze, futhi uhlelo lokulawula lwe-PC+PLC lwenza ukunemba kokulawula izinga lokushisa kunembe kakhudlwana futhi kuzinze.

Izinto zikagesi ziyimikhiqizo eyaziwa kakhulu ekhaya naphesheya, futhi i-Siemens PLC yasekuqaleni iqinisekisa ukuthi uhlelo luphephile futhi luzinzile.

Ukulawula izinga lokushisa kusebenzisa i-algorithm yokulawula i-PID yokuzilungisa, asikho isidingo sokusetha amapharamitha e-PID, ukunemba kokulawula okuphezulu

Imingcele yezobuchwepheshe

| Imodeli | I-CY-350B/T | I-CY-450B/T |

| Inombolo yendawo yokushisisa | Injini yokunyathela noma isilinda esingenanduku | |

| Inombolo yendawo yokupholisa | 6 ILITHA | |

| Umfutho womoya we-flux | 3-5BAR | |

| Imodi yokushisa kuqala | Umoya oshisayo omaphakathi/i-infrared | |

| Inombolo Yendawo Yokushisa Ngaphambili | 4 isigaba | |

| Ubude bokushisa | 1800 mm | |

| Isikhathi Sokufudumala | Cishe.15min | |

| Ubukhulu be-PCB ububanzi | 350mm | 450mm |

| Qondisa ububanzi | 50-350 mm | 50-450 mm |

| Isivinini se-Conveyor | 0-2000mm/min | |

| Ukuphakama kweConveyor | 750±20mm | |

| Isiqondiso sezokuthutha | L→R(R→L) | |

| Indlela yokudlulisa | 4-7° | |

| Izinga lokushisa le-solder | 9KW(Izinga lokushisa legumbi-300℃) | |

| Umthamo we-solder | 400Kg | 500Kg |

| Indlela yokulawula | Ikhompyutha Yomkhiqizo (iWindowsoperating system)+Siemens PLC | |

| Isivinini se-Conveyor | 3∮ AC380V 90W,Umkhiqizo: Tai Chuang | |

| Wave motor | 3∮ AC220V 360W*2pcs,Brand: Tai Chuang | |

| Iphampu yokuhlanza iminwe | I-1P AC220V 10W | |

| Iminwe | Uzipho olukhethekile lwe-titanium alloy double groove | |

| Isistimu yokupholisa | Ukupholisa umoya ngempoqo | |

| Ukunikezwa kwamandla | Izintambo ezi-5 3-isigaba 380V 50/60Hz | |

| Qala amandla | 38kw | |

| Amandla okusebenza ajwayelekile | Cishe i-10kw | |

| Imodi yokulawula izinga lokushisa | Ikhompiyutha egcwele ye-PID evaliwe yokulawula loop, idrayivu ye-SSR | |

| I-alamu engavamile | Izinga lokushisa elingavamile (phezulu kakhulu noma eliphansi kakhulu ngemva kwezinga lokushisa eliqhubekayo) | |

| Ukukhanya kwemibala emithathu | Ukukhanya kwesignali yemibala emithathu: ukushisa okuphuzi;izinga lokushisa eliluhlaza njalo;okubomvu-okungavamile | |

| Isisindo | Cishe.1800Kg | Cishe.2000Kg |

| Installationdimension (mm) | L4300×W1530×H1700mm | |

| Izidingo zomoya wokukhipha umoya | I-10 cube / min 2 i-isle∮200mm | |