01

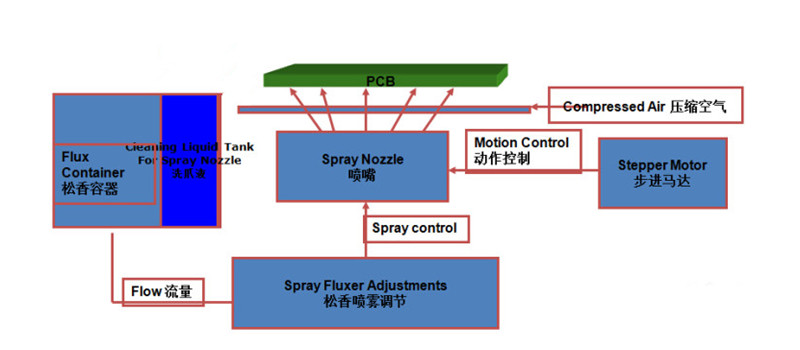

Spray System

Ngombobo we-Lumina (Japan), ububanzi besifutho buyi-20-65mm, ukuphakama kwenozzle ngu-50-80mm, kanti izinga lokugeleza eliphezulu lingu-60ml/min.

Isebenzisa isihlungi se-AirTAC (Taiwan), isikali sesikhombi sibonisa ingcindezi yomoya, wonke amapayipi esistimu yokufafaza ane-asidi namapayipi okuvikela ukugqwala amelana ne-alkali.

Isistimu yokufafaza isebenzisa indlela yokuskena yokufafaza, ukushintshwa komkhawulo kanye nokubona kokungena kuhlangene ukuze kulawuleke, futhi i-PCB itholwa ngokuzenzakalelayo ngokufafaza okungenasici ngokuya ngesivinini nobubanzi be-PCB, ukuze uhla lokumanzisa lokugeleza lube nomphumela omuhle kakhulu.Ikhanda lokufafaza le-inlet kanye ne-steping motor kusebenza kahle, kuzinzile futhi kuthembekile.

I-stainless steel bent forming tray isetshenziswa ngaphansi kwekhanda lesifutho ukuze kulayishwe amanzi angcolile kanye ne-flux, angakhishwa futhi ahlanzwe ngokuthanda kwakhe.

Isistimu yokukhipha umoya iwuhlelo lokutakula oluzenzakalelayo oluphakeme olunezingqimba ezintathu zokuhlunga kwensimbi engenasici ukuze kuncishiswe ukuvaleka kwensalela eguquguqukayo epayipini elikhipha umoya ngokusebenzisa izici zoketshezi ukuhlunga ukugeleza okweqile.

Ummese womoya we-pneumatic, ovunguza ukugeleza okukhulu ngesikhathi sokufafaza ethangini lokutakula ukuvimbela ukugeleza kungangeni endaweni yokushisa futhi kuqinisekiswe ukuphepha kokukhiqiza.

Konke ukusekelwa kwensimbi engagqwali + i-aluminium alloy, ukuhlanza nokugcinwa kalula, ukumelana nokugqwala okuqinile, kuhlala isikhathi eside.

02

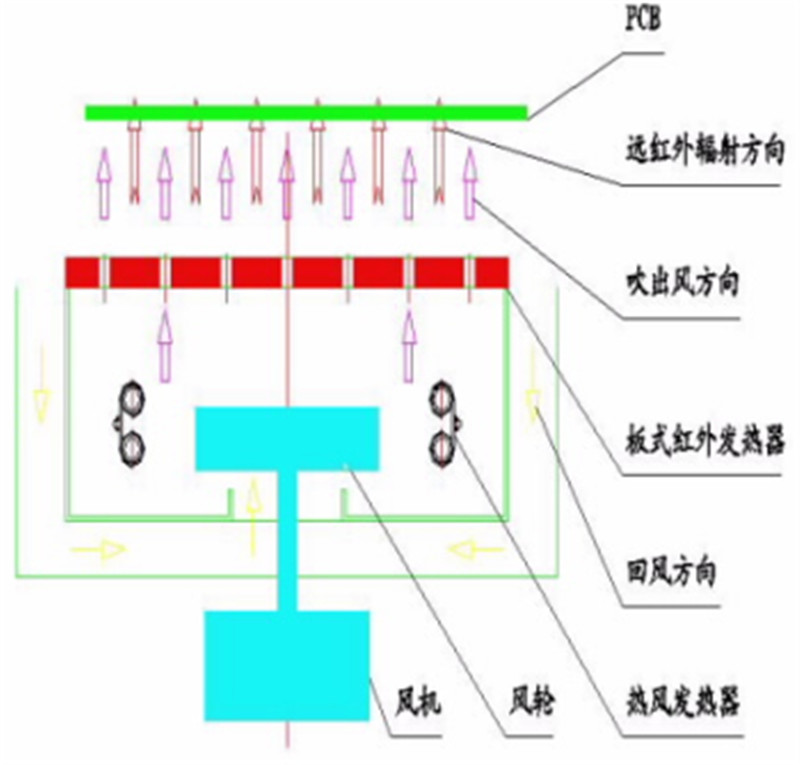

Isistimu Yokushisa

"Far Infrared + Hot Air" Isimiso Sokushisa Esihlanganisiwe

I-Porous plate heater isetshenziswa njengomthombo wokushisisa we-infrared futhi ukungena kokukhanya kwe-infrared kude kusetshenziselwa ukushisa ngokuqondile i-PCB, ngaleyo ndlela kugwenywe inkinga yomthamo onganele wokushisa kwimodi yendabuko yokushisa egcwele.

Ukushisa okuhlanganisiwe, ikakhulukazi ukufudumeza kwe-infrared, okuhambisana nokuguquguquka komoya oshisayo, kungathuthukisa amandla okushisa nokushisa okufanayo.

Injini yomoya oshisayo oshisayo ingenisiwe ivelaSanyue(Taiwan).Intambo yokushisisa i-nickel winding futhi impilo yayo yesevisi iba ngcono kakhulu.

Idizayini ye-modular yokukhipha isiza ukugcinwa komqhubi

03

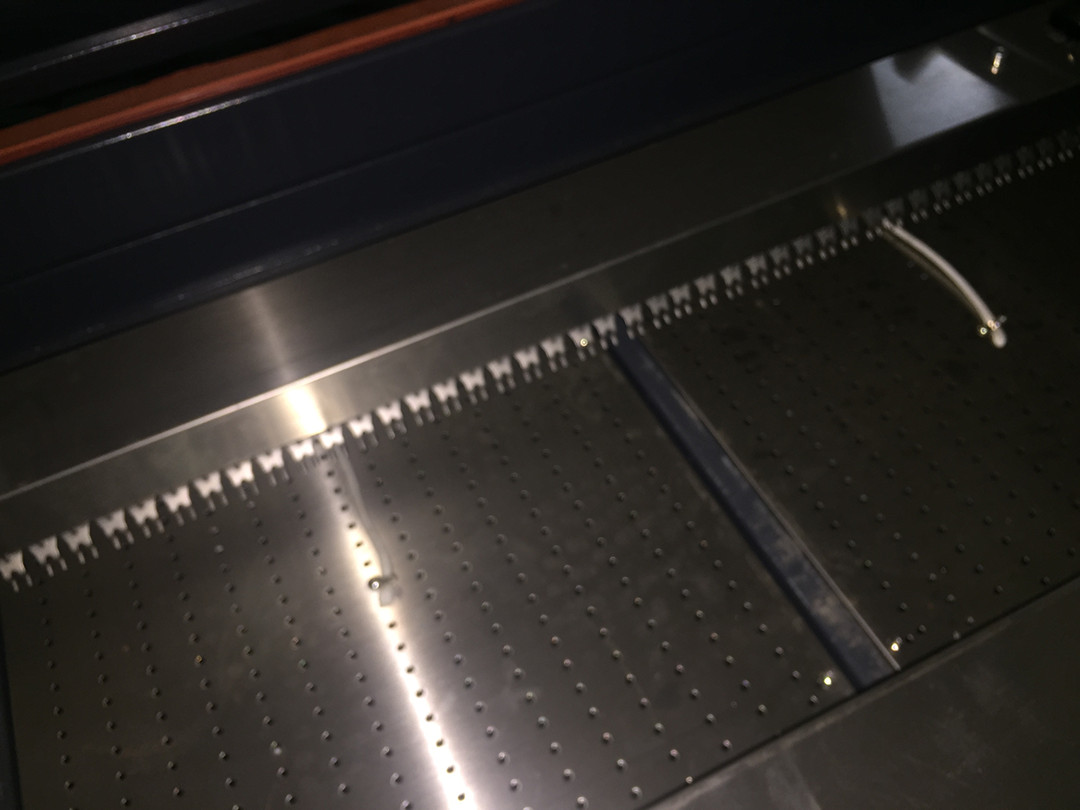

Welding System

4mm SUS316L isinye esingenisiwe sensimbi engagqwali, uhlobo olusha lwedizayini yesinye, ukubukeka okuhle, ukuhlanza okulula, ipuleti lokushisisa lensimbi, akukho ukuguquguquka kwesinye.

Ububanzi beak obushintshekayo ukuze kuncishiswe i-tin oxidation, ekhiphekayo ngaphandle kokukhipha umlomo wombhobho

Isikhundla se-impeller shaft sandisa isihlangu se-oxidation futhi sinciphisa i-tin oxide ekhiqizwa ukujikeleza kwe-impeller shaft.

I-impeller shaft kanye nezingxenye ze-peak motor zingasuswa ngokuhlukana ngaphandle kokukhipha ithrekhi yethayela (enye i-brand peak welding ayikwazi ukwenza lo mklamo).

I-tin slag oxidation: kusetshenziswa ipuleti le-PCB elingu-200*200 mm njengepuleti lokuhlola nokubala kuma-pcs angu-300 ngehora, inani le-tin slag elikhiqizwa ngamahora angu-10 ngu-2KG.

04

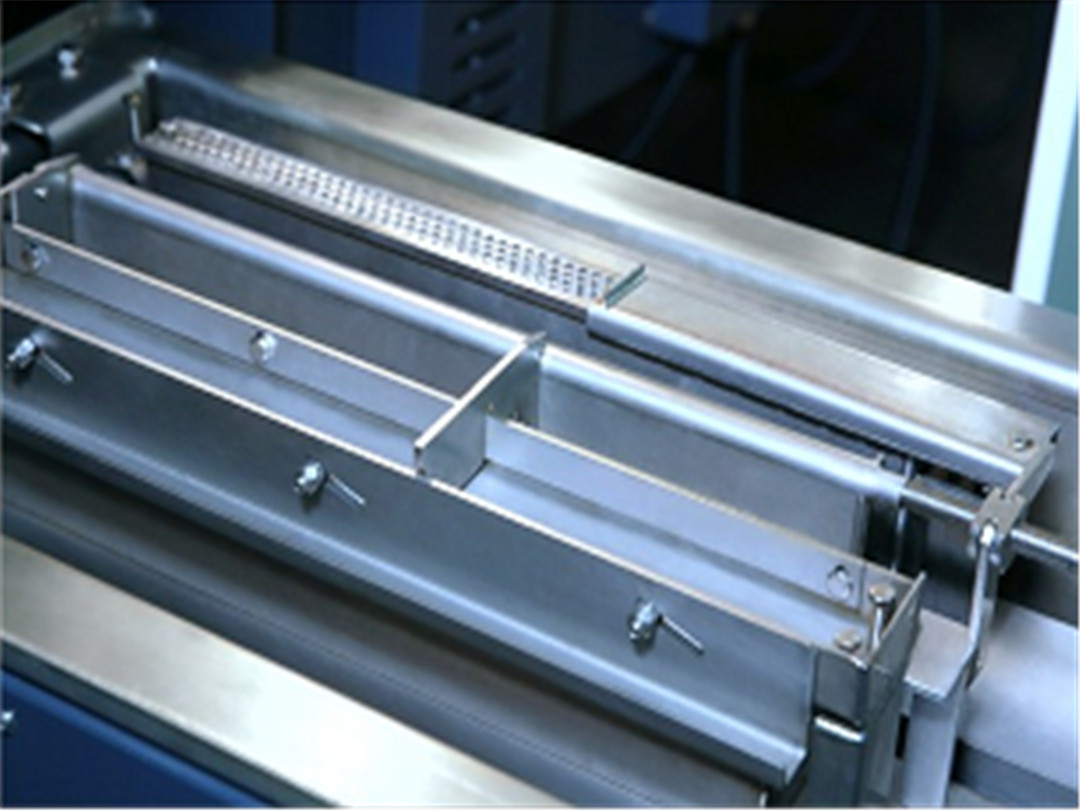

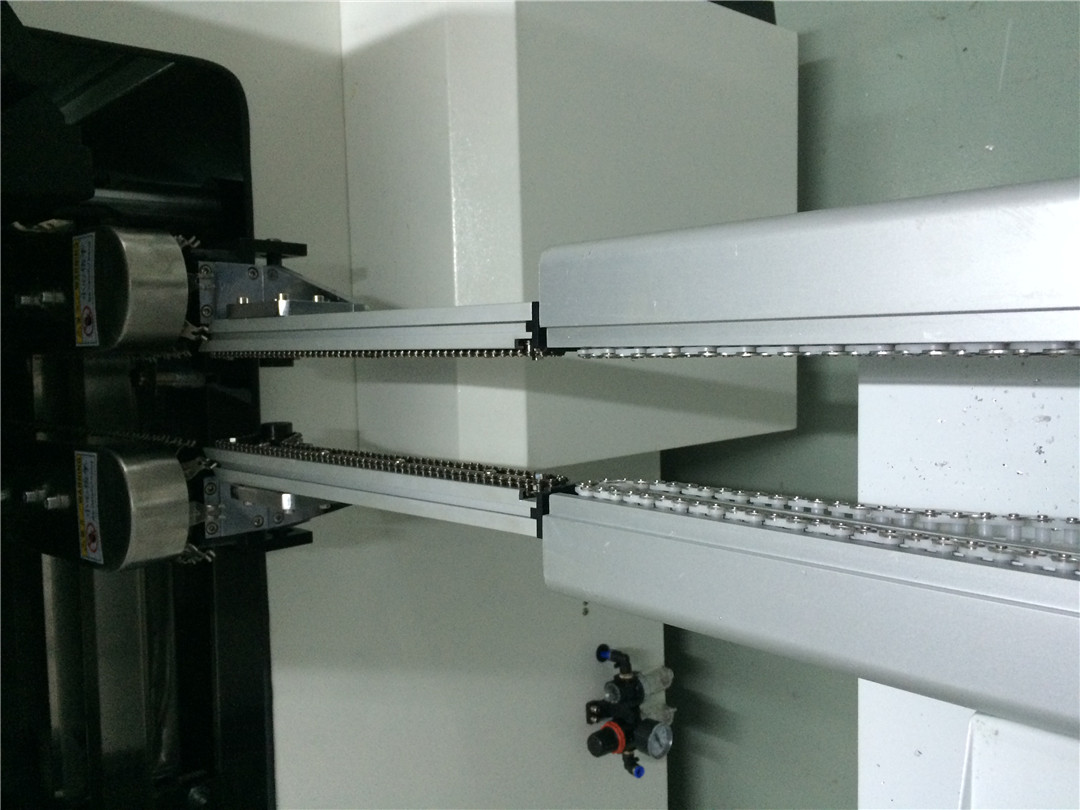

Uhlelo Lokulawula Isistimu Yezokuthutha

Umshini wokuphakelayo ozenzakalelayo noxhumayo we-aluminium emsulwa, ipuleti lokuphakelayo elibushelelezi nelizinzile.

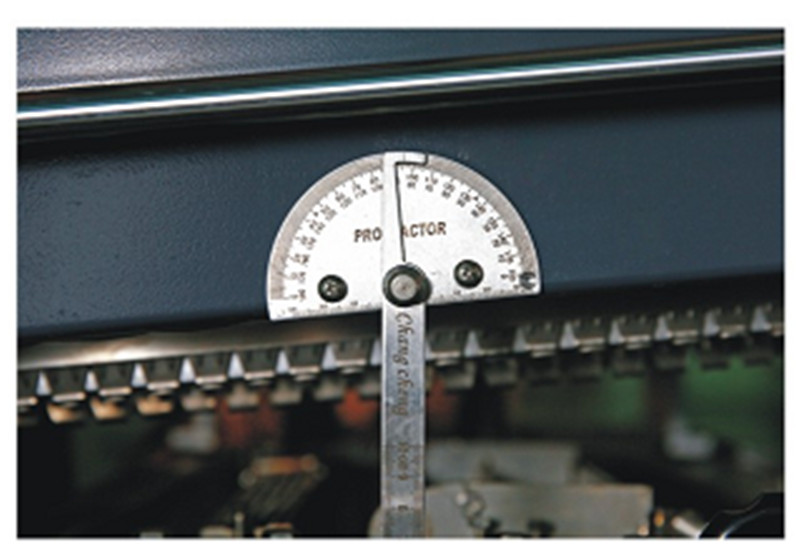

Umzila wesitimela unedivayisi yawo ye-engeli yokuthambekela, engaqapha ngokunembile i-engeli yokuthambekela futhi ilawule ikhwalithi yebhodi elidlulayo.

I-Titanium heavy-duty double hook chain claw iqinisekisa ukuthi akukho ukungcoliswa kwethayela kanye nesigaba esi-3 sikaloliwe ongaguquki uqinisekisa ukuthi akukho ukuvulwa kwezimpondo, okuvimbela ngempumelelo isitimela esiqondisayo ukuthi singawi futhi siboshwe.

Ibha yethusi engu-4 mm yezokuthutha ezibushelelezi nezizinzile.Ezinye izinhlobo eziningi zisebenzisa ibha yensimbi engagqwali, engakwazi ukuqinisekisa ukuhamba okubushelelezi isikhathi eside.

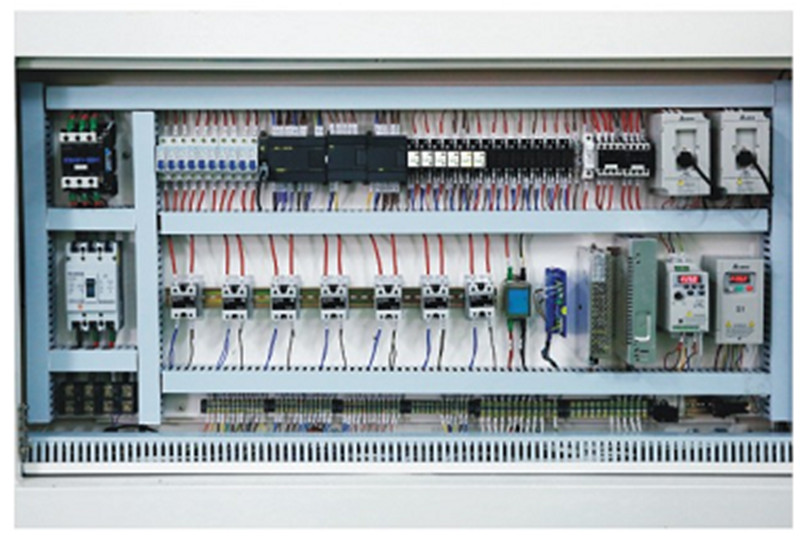

Uhlelo lokusebenza olulula lusiza ukusebenza kwabasebenzi, uhlelo lokulawula i-PC+PLC lwenza ukulawula izinga lokushisa kucace kakhudlwana futhi kuzinze.

Izinto zikagesi ziyimikhiqizo eyaziwayo ekhaya naphesheya.I-Original Siemens PLC iqinisekisa uhlelo oluphephile futhi oluzinzile.

Ukulawula izinga lokushisa kusebenzisa i-algorithm yokulawula ye-PID yokuzishuna, ngaphandle kokusetha okwenziwa ngesandla kwamapharamitha e-PID, ngokunemba kokulawula okuphezulu.

Imingcele Yezobuchwepheshe

| Imodeli | CY-450B(4 izindawo) |

| Indlela yokulawula | Ikhompyutha ye-Dell (Windows7)+Siemens PLC Ikhompyutha yokulawula izimboni+PLC |

| I-Conveyor motor | 3∮ AC380V 90W, Tai Chuang |

| Usayizi we-PC | 50-450mm(w) |

| I-Preheating Zone | Amandla: Ubude be-16KW: (1800mm 4sections control PID |

| Izinga lokushisa le-solder | 9KW (Izinga lokushisa legumbi -300℃) |

| Umthamo we-solder | 500Kg |

| Wave motor | 3P AC 220V 0.36KW*2pcs,Brand:Taichuang |

| Iphampu yokuhlanza iminwe | I-1P AC220V 6W |

| Isistimu yokupholisa | Ukupholisa umoya ngempoqo |

| PCB isiqondiso ezokuthutha | L→R /(R→L) |

| Ukunyakaza kweNozzle | i-stepper motor noma i-SMC rodless cylinder |

| Umthamo we-flux | 6 ILITHA |

| Umfutho womoya we-flux | 3-5BAR |

| I-engeli ye-Conveyor | 4-7℃ |

| Ukunikezwa kwamandla kagesi | I-3P AC380V 50Hz |

| Amandla ajwayelekile/aqalayo | 28KW/8KW |

| Isisindo sengqikithi | 1400KG |

| Isistimu yokupholisa | Ukupholisa okuphoqelekile |

| Ubukhulu | 3800 (L) x1360 (W) x1700mm (H) |

| Ukubukeka | 4400 (L) x1400 (W) x1700mm (H) |